At Gemme Plast, we have deep knowledge and vast experience in the processing of all technical plastic materials. We are particularly expert in the molding of polypropylene (PP) and PVDF, even with different percentages of fillers, to offer customized solutions for every need.

We know that aesthetics are just as important as functionality. By using different masterbatches, we can customize your products, transforming them from matte to bright and colorful, to meet every design need.

PP (Polypropylene)

Fluorinated(ECTFE – ETFE – PFA – PVDF)

ABS (Acrylonitrile– Butadiene – Styrene)

PS (Polystyrene)

PA (Polyamides)

PARA (polyarylamide)

PMMA (polymethylmethacrylate)

POM (polyoxymethylene)

PC (polycarbonate)

PE (polyethylene)

PVC (polyvinyl chloride)

PPS (polyphenylene sulfide)

PEEK (polyetheretherketone)

Environmental sustainability is a core value for Gemme Plast. Therefore, we promote the use of recycled materials, such as recycled polypropylene, with a view to a circular economy.

We know that aesthetics are as important as functionality. Thanks to the use of different masterbatches, we can customize your products, transforming them from opaque to bright and colorful, to satisfy every design need.

Below we provide a list of technical polymers that can be injected at Gemme Plast.

It’s a semi-crystalline thermoplastic polymer, belonging to the polyolefin class, that can be used in a wide variety of applications thanks to its easy processing.

PP has a good resistance to temperature and chemical solvents –both acids and bases -.

These qualities make PP the most broadly used thermoplastic material in the automotive and synthetic fibers industry. Because of its lower values of traction and compressive resistance, it’s often used in a compound with different fillers, such as:

-Glass fiber: adding PP to this fiber allows us to obtain structural advanced materials with high mechanical resistance and resilience.

-Carbon fiber: this fiber gives lightness and high mechanical resistance to the compound. It’s commonly used in those applications in which the highest performance is required.

-Talc: this filler increases creep resistance and elastic modulus.

Its operative temperature range is +0°C / 90°C.

These are technopolymers used in high-technology applications or particularly aggressive environments.

PVDF (Polyvinylidene fluoride): it’s a partly fluorinated polymer, much easier to work than other fluoropolymers.

It has excellent chemical resistance and better values of mechanical strength than other fluorinated polymers.

The rigidity, the anti-friction qualities and the high abrasion resistance make the PVDF suitable for applications in which high-temperature stability is required.

In order to further improve its mechanical properties, keeping a low specific weight, PVDF can be filled with carbon fiber.

Its operative temperature range is: -40°C / 150°C.

This is an amorphous copolymer belonging to the styrene resins class, with excellent mechanical properties.

Tough and strong at low temperatures too, ABS has high hardness and good breaking and scratching resistance.

It does not resist benzol, oil and solvents. Adding glass fiber, ABS increases the elastic modulus and the mechanical resistance but at the expense of tenacity. It’s widely used in the manufacturing of automotive components and pipelines.

Its operative temperature range is -40°C / +80°C.

It is a synthetic aromatic polymer. Under normal conditions, PS has a hardness, rigidity and transparency, but also brittleness. Chemically inert to many corrosive agents, PS is soluble in solvents such as acetone and benzene. It can be used as a compound to improve its mechanical, chemical and light resistance properties.

Its operative temperature range is -40°C / +70°C.

Polyamide, commonly known as Nylon, is a thermoplastic material, widely appreciated for its mechanical properties. It has a low friction coefficient and good wear resistance.

Properties and temperature range depend on the type of polyamide, classified according to the carbon atoms number in the main chain. The most common types of PA are PA6, PA6.6, PA11.

-Nylon 6: effective in normal conditions, it quickly absorbs moisture and loses resistance as temperature increases. Nevertheless, it can easily be machined and it is used in fiber production. Its melting point is about 228°.

-Nylon 6,6: a very common commercial polyamide, Nylon 6,6 is a crystalline translucent material, with a melting point of 269° that makes it the most high-temperature resistant PA. In normal conditions it absorbs more than 2% of moisture from the air: absorbed water increases shock resistance and flexibility in moist environments.

-Nylon 11: it has good hardness and shock and abrasion resistance, although its mechanical properties are lower than other PA.

For its extraordinary moisture absorption power, it’s not recommended the use in wet areas.

PA with molybdenum disulfide is usually distinguished by fiberglass-fulfilled PA, characterized by a higher elastic modulus.

It’s an aromatic filled with glass fiber. to obtain a high breaking resistance comparable to that of some metals. For its rigidity, chemical resistance and ease of processing it can be used in the transport, medical and electronic industries.

Its operative temperature range depends on the type, up to 130°.

It’s an amorphous polymer, commonly known as Plexiglas. Its main properties are brightness and transparency. For this reason, it can be used as an alternative to glass in articles for which resistance to sun rays and weather agents is required.

Maximum operative temperature: +60°C

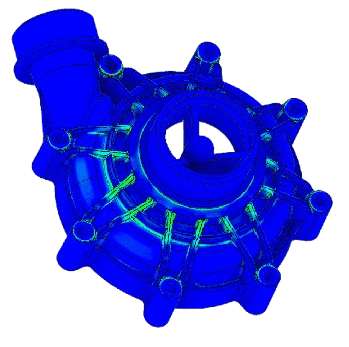

Crystalline polymer also known as acetal resin. It has good chemical resistance, with high hardness, tenacity and dimensional stability. These properties make POM suitable for mechanical components (gears, bushes, pipe fittings, pump bodies). To further improve its mechanical qualities, POM is often filled with glass or carbon fiber.

The operative temperature range is from -40°C to +80°C.

This polymer is often used as a glass replacement for its transparency and impact resistance. It’s light, strong and easy to process. It has a low absorption capacity and a good chemical resistance to oil, organic solvents and greases. PC typical applications are in the automotive, medical, building and consumer goods industries.

Its operative temperature changes, according to the PC type, from -190° to 130°.

It’s the most common plastic. It can be classified by its density and branching:

HDPE (High-Density Polyethylene): this polymer is a little branched, with more hardness and tensile strength than LDPE, and it can also resist higher temperatures (up to 110°).

LDPE (Low-Density Polyethylene): it has more branching than the HDPE, giving it less mechanical resistance but greater resilience. It can resist high temperatures up to 80° and has an excellent chemical resistance to diluted acid or basic solutions, alcohols and esters.

PE is broadly used in food packaging, the chemical industry and the automotive sector.

Amorphous thermoplastic material that has a high elastic modulus and excellent impact resistance. Its chemical resistance to acids is mainly used in the galvanizing and petrochemical industry.

The application temperature range is from -10°C to +70°C.

It’s a high-performance semi-crystalline technopolymer that has a low moisture absorption power. Because of its high-temperature resistance (up to 210°) and its chemical resistance to corrosive liquid, PPS is often used for acid pump impellers. Generally, it’s widely used in pumping, electricity, automotive sector. It can be also filled with glass fibers to increase thermal stability and hardness.

Semi-crystalline thermoplastic polymer with excellent mechanical and chemical performance, in high temperature context too. Its melting point is relatively very high (about 340°).

Easy to process in solid form, PEEK has good abrasion and wear resistance, with a high elastic modulus.

For its properties, PEEK is used in different sectors (medical, aeronautic, automotive), when extreme conditions resistance is required.

Other materials upon request

© Copyright All Rights Reserved © 2025 Gemme Plast Srl – Share Capital: 10,000.00 i.v. – C.C.I.A.A. VARESE no. 366391 – VAT and Tax Identification Number 03621490121

Authored by GEDINFO.COM