For over 40 years at Gemme Plast, we have been committed to providing high-quality injection molding services for technical plastics and high-performance polymers, including fluoropolymers.

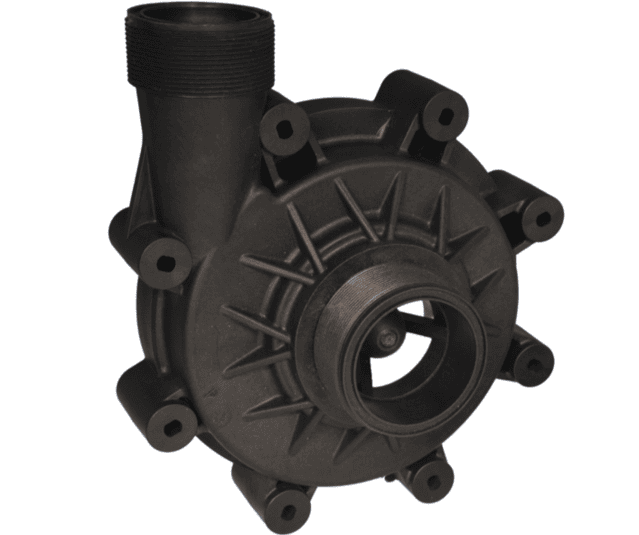

We specialize in the creation of small and medium series, offering a complete and personalized service that ranges from the conception of the piece to the finished product.

At Gemme Plast, we can offer a complete service at every stage of the production process, according to the customer’s needs, starting from their initial idea to the finished product, with a complete and customized injection molding process.

Our starting point is the customer's vision. We communicate to fully understand the needs, analyze the idea, and offer specialized technical advice. We want to ensure we grasp every detail of the project, to turn it into a concrete success.

our Technical Department, drawing on extensive experience, carefully examines the project to identify any critical issues and propose improvement solutions. We analyze the technical and economic feasibility, evaluating materials, processes, and necessary optimizations to ensure the best possible result.

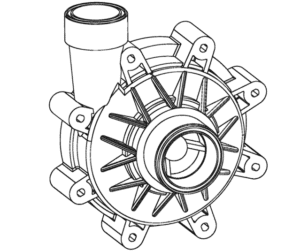

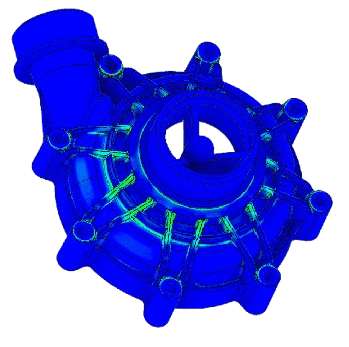

we give shape to your idea through 3D design. We create three-dimensional models, both starting from an existing sample and developing the piece from scratch. We use advanced FEM software to simulate the behavior of the piece, verify its structural capabilities and define the desired surface qualities.

we use the latest generation software to design complex and high-performance injection molds. Our team of experts carefully analyzes the customer's project to define the mold specifications and meet their expectations.

before starting production, we carry out a mold test to verify the functionality and effectiveness of the mold produced. This phase is essential to ensure that the final product meets the highest quality standards.

after validating the mold, we are ready to start production. Thanks to our experience and the flexibility of our molding department, we can guarantee a quick and efficient start-up, respecting the agreed times and budgets.

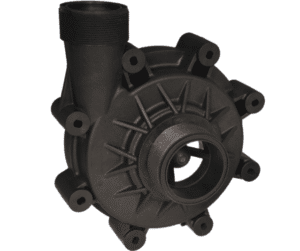

the final result is a high-quality product, made with precision and attention to detail. Our commitment is to offer a product that meets expectations.

Thanks to our know-how and the use of advanced technologies, we can offer numerous advantages to our customers:

Our experience in the injection molding of small and medium series allows us to create a wide range of products:

We collaborate with companies from different industrial sectors, including:

Precision components for industrial machinery, equipment and tools.

Solutions for the energy sector, including components for plants, equipment and energy production systems.

Medical devices, electromedical equipment and components for the healthcare sector.

Components for machine tools, plastic processing machines, packaging machines and other types of industrial machinery.

Technical parts and components for automobiles

Components for electronic equipment, connectors, supports, and customized housings

© Copyright All Rights Reserved © 2025 Gemme Plast Srl – Share Capital: 10,000.00 i.v. – C.C.I.A.A. VARESE no. 366391 – VAT and Tax Identification Number 03621490121

Authored by GEDINFO.COM